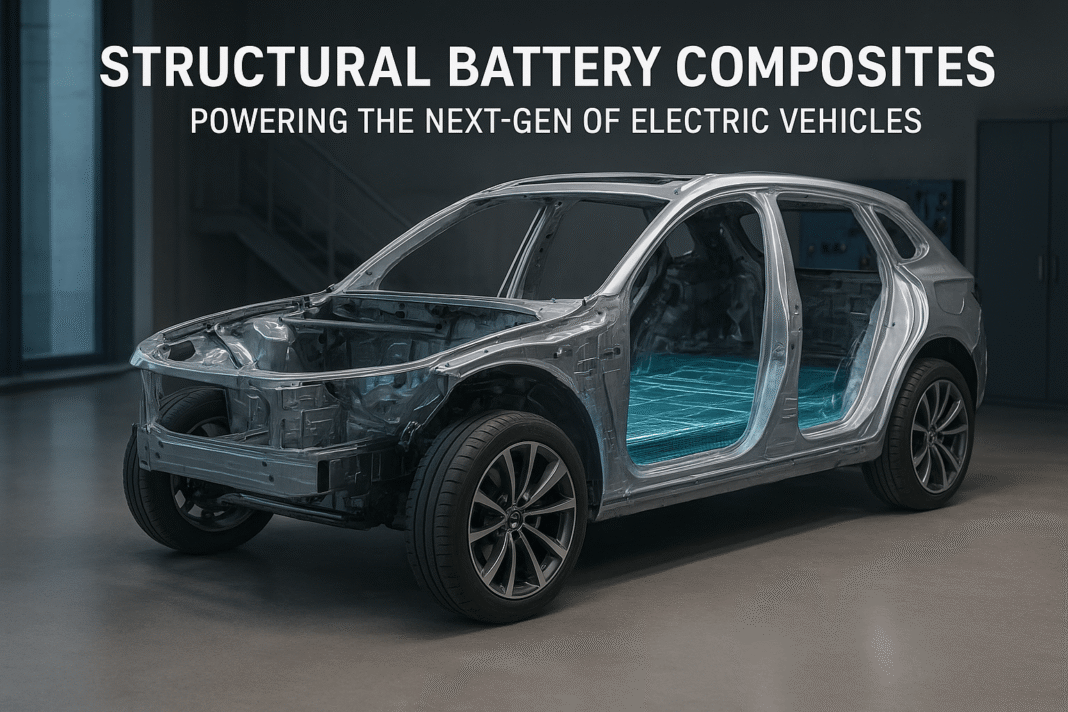

The global shift toward electric mobility is accelerating—but one major hurdle remains: battery weight. Traditional lithium-ion batteries, though powerful, add significant mass to electric vehicles (EVs), reducing range and efficiency.

The answer to this challenge lies in structural battery composites (SBCs)—a breakthrough technology that can make EVs both lighter and stronger by turning the vehicle’s body itself into the battery.

What Are Structural Battery Composites?

Structural battery composites are multifunctional materials that combine two essential functions:

-

Energy Storage: Like a regular battery, they store and deliver power.

-

Structural Strength: They serve as part of the car’s physical frame or body panel.

In simple terms—the car’s structure is the battery.

This means fewer separate battery packs, less weight, and better efficiency.

How Structural Batteries Work

Rather than hosting battery cells in a separate compartment, structural batteries integrate energy-storing fibers (like carbon fiber) and electrolytes directly into the car’s body material.

The result:

-

A single, unified material that powers the vehicle.

-

Enhanced strength and rigidity.

-

A significant reduction in total vehicle mass.

Benefits for Electric Vehicles

Weight Reduction

SBCs can reduce total battery weight by up to 30–40%, boosting range and handling.

Improved Safety

These materials distribute energy more evenly, minimizing fire risk and crash damage.

Increased Efficiency

With less weight to carry, vehicles achieve better energy density and performance.

Sustainability

Fewer raw materials and less waste make SBCs more environmentally friendly than conventional battery packs.

Current Innovations & Research

-

Volvo and Sweden’s Chalmers University are leading the charge in structural battery development.

-

Tesla is exploring “body-as-battery” concepts through its large casting approach.

-

Universities and startups are experimenting with resin-based electrolytes that can be shaped into car frames, airplane wings, and even spacecraft panels.

As of 2025, these technologies are transitioning from lab-scale prototypes to real-world testing in EVs and aerospace manufacturing.

Challenges Ahead

While promising, SBCs face several hurdles before full commercialization:

-

Energy Density: Current SBCs hold less energy than traditional lithium-ion cells.

-

Manufacturing Complexity: Integrating electrical and mechanical properties is difficult at scale.

-

Maintenance: Damage to a structural battery could impact both safety and power.

But as material science improves, these challenges are rapidly shrinking.

The Future of Mobility

The next era of EVs will likely feature structural energy storage—where body, battery, and function blend seamlessly.

Imagine:

-

Lighter EVs with greater range.

-

Airplanes that store power within their wings.

-

Even drones and satellites with built-in power sources.

This is not just evolution—it’s a redefinition of energy storage.

Conclusion

Structural battery composites mark a quantum leap in electric vehicle design—combining performance, sustainability, and innovation.

As technology matures, it will drive a new generation of EVs that are lighter, faster, and far more efficient.

The era of “battery-as-structure” has begun—and it’s redefining what mobility means for the next decade.