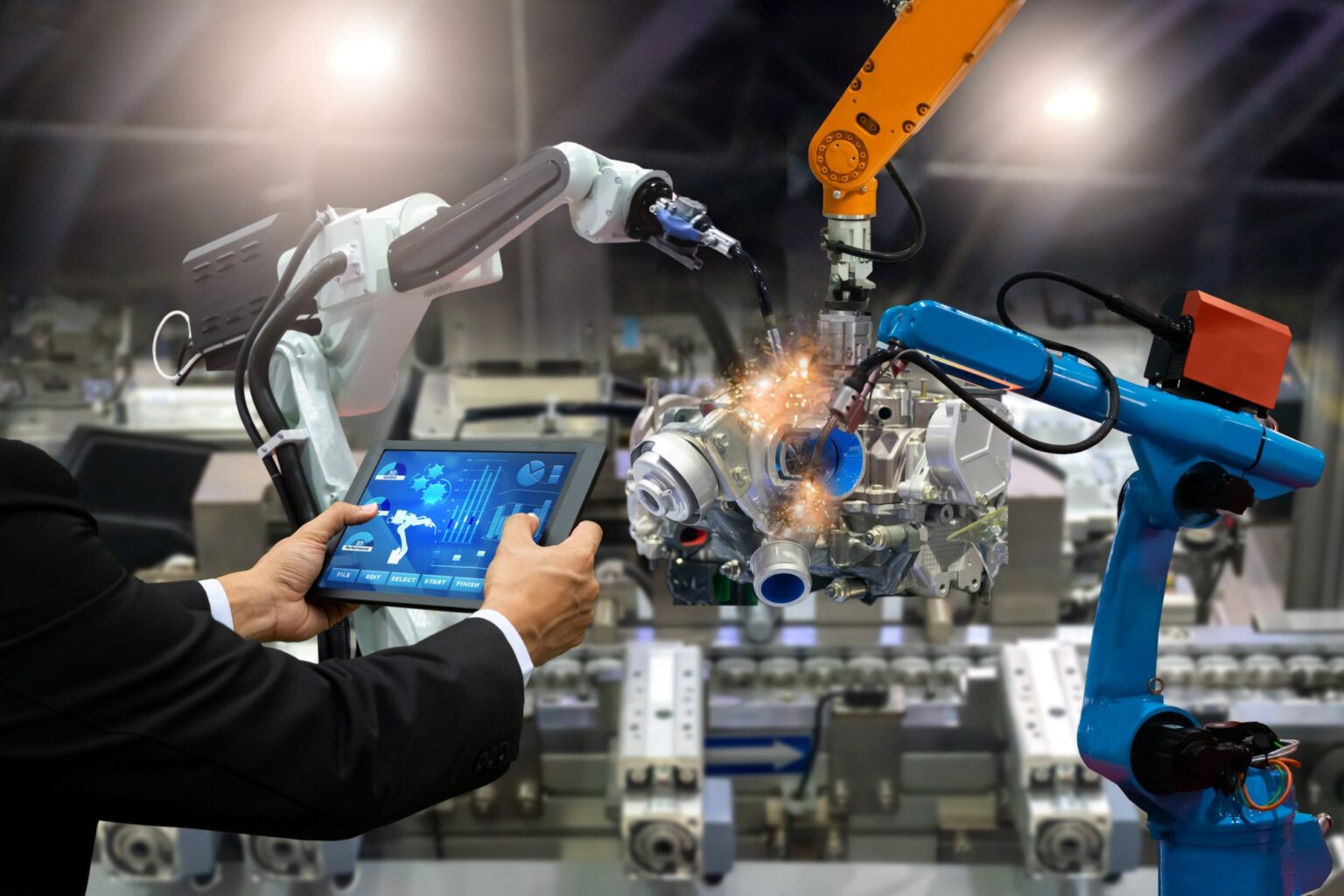

Robotics and automation technologies have significantly enhanced efficiency and quality in the manufacturing industry. These technologies automate various tasks, reduce human error, improve productivity, and enable greater precision. Here are some key aspects highlighting the significance of robotics and automation in manufacturing:

- Increased Efficiency: Robotics and automation systems can perform repetitive tasks with consistent speed and accuracy, resulting in increased efficiency and productivity. By automating manual and repetitive processes, manufacturers can optimize production cycles, reduce cycle times, and achieve higher output levels.

- Improved Quality and Consistency: Robots and automated systems perform tasks with a high degree of precision, minimizing errors and defects. They consistently follow programmed instructions, leading to uniform product quality and reducing variations in production. Automated quality control systems can also detect and reject defective products, ensuring only high-quality items reach the market.

- Enhanced Safety: Automation allows for the transfer of hazardous or physically demanding tasks from humans to robots. This improves workplace safety by reducing the risk of accidents and injuries. Robots can handle tasks involving heavy lifting, working in extreme temperatures, or dealing with toxic substances, creating a safer environment for workers.

- Flexibility and Adaptability: Modern robotics systems offer flexibility and adaptability to changing production needs. Robots can be easily reprogrammed and reconfigured to perform different tasks or adapt to new product designs. This enables manufacturers to quickly switch between product lines, accommodate customization requests, and respond to market demands more effectively.

- Increased Speed and Precision: Robots and automated systems can work at high speeds and with consistent accuracy. This leads to faster production cycles, shorter lead times, and improved time-to-market for products. Precision in tasks such as assembly, machining, and packaging ensures that products meet precise specifications and quality standards.

- Reducing Costs: While the initial investment in robotics and automation may be significant, the long-term benefits include cost savings. Automated systems can operate 24/7, reducing labor costs associated with shift work and overtime. Additionally, automation reduces material waste, improves energy efficiency, and minimizes rework, resulting in overall cost reductions.

- Collaborative Robots (Cobots): Collaborative robots, or cobots, are designed to work safely alongside humans, enhancing cooperation between humans and machines. Cobots can perform tasks that require human dexterity, while also benefiting from the speed and precision of automation. They can assist workers in assembly, material handling, and other manual tasks, augmenting human capabilities and increasing productivity.

- Data Collection and Analysis: Robotics and automation systems generate vast amounts of data that can be collected and analyzed to improve operations. By integrating sensors and monitoring systems, manufacturers can gather real-time data on production processes, equipment performance, and product quality. Data analytics enable predictive maintenance, process optimization, and continuous improvement initiatives.

Robotics and automation technologies have revolutionized the manufacturing industry, enabling manufacturers to achieve higher productivity, improved quality, and operational excellence. By leveraging these technologies, manufacturers can gain a competitive edge, streamline operations, and meet the evolving demands of the market.