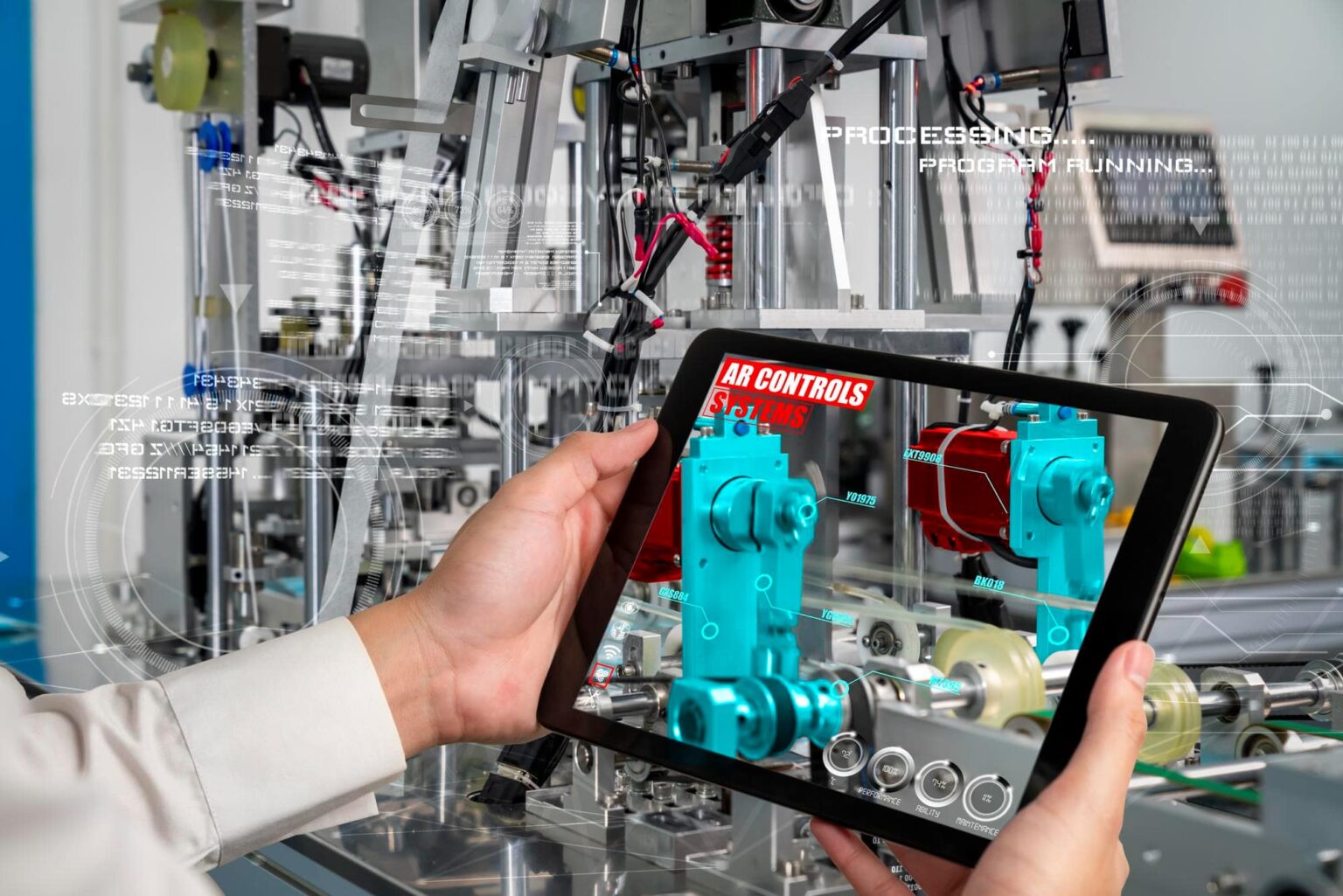

Cyber-Physical Systems (CPS) refer to the integration of physical systems with digital technologies, creating a seamless connection between the physical and virtual worlds. In the context of manufacturing, CPS integrates the physical manufacturing processes with digital systems, enabling advanced monitoring, control, and optimization. Here are some key aspects highlighting the significance of Cyber-Physical Systems in manufacturing:

- Interconnectivity: CPS leverages Internet of Things (IoT) devices, sensors, and actuators to connect physical manufacturing assets, such as machines, equipment, and products, to digital systems. This interconnectedness enables real-time data collection, communication, and collaboration between various components of the manufacturing process.

- Real-Time Monitoring and Control: CPS enables real-time monitoring and control of manufacturing processes. Sensors embedded in machines and equipment gather data on parameters such as temperature, pressure, speed, and vibration. This data is transmitted to digital systems, where it can be analyzed, visualized, and used to make informed decisions and adjustments in real-time.

- Predictive Maintenance: By continuously monitoring the condition of machines and equipment, CPS facilitates predictive maintenance. Data collected from sensors and other sources can be analyzed to detect early signs of equipment failure or performance degradation. Predictive maintenance allows manufacturers to schedule maintenance activities proactively, minimizing downtime and maximizing productivity.

- Optimization and Automation: CPS enables optimization and automation of manufacturing processes. Real-time data and analytics can be used to identify bottlenecks, optimize workflow, and streamline operations. Automation systems, driven by digital intelligence, can control and coordinate various aspects of production, leading to improved efficiency, reduced waste, and increased productivity.

- Enhanced Product Quality: CPS enables manufacturers to ensure and improve product quality. Real-time monitoring and control systems can detect deviations from quality parameters, trigger alerts, and initiate corrective actions. By integrating quality control mechanisms within the production process, CPS helps in achieving consistent product quality and reducing defects.

- Virtual Simulation and Digital Twin: CPS facilitates virtual simulation and the creation of digital twins. Digital twins are virtual replicas of physical manufacturing assets, processes, or products. They can be used for simulation, testing, and optimization before implementing changes in the physical environment. Digital twins enable manufacturers to model and analyze the behavior of their systems, identify potential issues, and optimize performance.

- Supply Chain Integration: CPS extends its impact beyond the manufacturing floor and integrates with the broader supply chain. By connecting with suppliers, logistics providers, and customers, CPS enables end-to-end visibility and coordination. It allows for real-time demand sensing, inventory management, and efficient logistics, leading to improved supply chain performance and customer satisfaction.

- Cybersecurity Considerations: As CPS involves the integration of physical and digital systems, cybersecurity becomes a critical aspect. Protecting the integrity, confidentiality, and availability of data and systems is essential. Robust cybersecurity measures, such as secure communication protocols, access controls, and intrusion detection systems, need to be implemented to safeguard against cyber threats and unauthorized access.

CPS revolutionizes manufacturing by integrating digital and physical systems, enabling real-time monitoring, control, and optimization. It enhances efficiency, productivity, and product quality while enabling predictive maintenance, automation, and supply chain integration. The seamless connection between the physical and digital worlds through CPS paves the way for smarter, more agile, and interconnected manufacturing processes.