Advanced materials and nanotechnology have significant implications for manufacturing industries, offering improved performance, enhanced functionality, and novel applications. These technologies enable the development of materials with unique properties at the nanoscale, allowing manufacturers to create innovative products and optimize existing manufacturing processes. Here are some key aspects of advanced materials and nanotechnology in manufacturing:

- Nanomaterials: Nanomaterials possess unique properties due to their small size and high surface area-to-volume ratio. They exhibit enhanced mechanical strength, thermal stability, electrical conductivity, and optical properties. Manufacturers can incorporate nanomaterials such as nanoparticles, nanocomposites, and nanofibers into their products to enhance their performance and functionality. For example, carbon nanotubes can improve the strength and conductivity of composite materials used in aerospace and automotive applications.

- Lightweight Materials: Advanced materials, including nanomaterials, offer the opportunity to develop lightweight alternatives with comparable or superior properties to traditional materials. Lightweight materials are particularly valuable in industries such as aerospace, automotive, and transportation, where weight reduction can lead to improved fuel efficiency and increased performance. Carbon fiber reinforced composites, for instance, provide high strength-to-weight ratios, making them ideal for aerospace structures.

- Smart Materials: Smart materials, such as shape memory alloys, piezoelectric materials, and self-healing polymers, can change their properties in response to external stimuli. These materials can be used to create products with adaptive capabilities, such as self-repairing structures, sensors, and actuators. Smart materials find applications in areas like healthcare, robotics, and infrastructure, offering improved functionality and efficiency.

- Coatings and Surface Modifications: Advanced materials and nanotechnology enable the development of specialized coatings and surface modifications. Nanostructured coatings can provide enhanced wear resistance, corrosion resistance, and improved surface properties. They can also be designed to have specific functionalities, such as antibacterial or self-cleaning properties. These coatings find applications in various industries, including automotive, aerospace, electronics, and healthcare.

- Energy Storage and Conversion: Advanced materials play a crucial role in energy storage and conversion technologies. For example, nanomaterials like graphene and lithium-ion batteries with nanoscale components have revolutionized energy storage, enabling high-capacity, fast-charging, and longer-lasting batteries. Nanomaterials are also used in photovoltaic cells for improved energy conversion efficiency, contributing to the development of sustainable energy solutions.

- Additive Manufacturing: Nanotechnology has had a significant impact on additive manufacturing, commonly known as 3D printing. Nanomaterials, such as metal nanoparticles and nanocomposites, can be used as printing materials, offering improved mechanical properties and increased design flexibility. Nanoscale resolution in 3D printing enables the production of complex structures and miniaturized components with high precision.

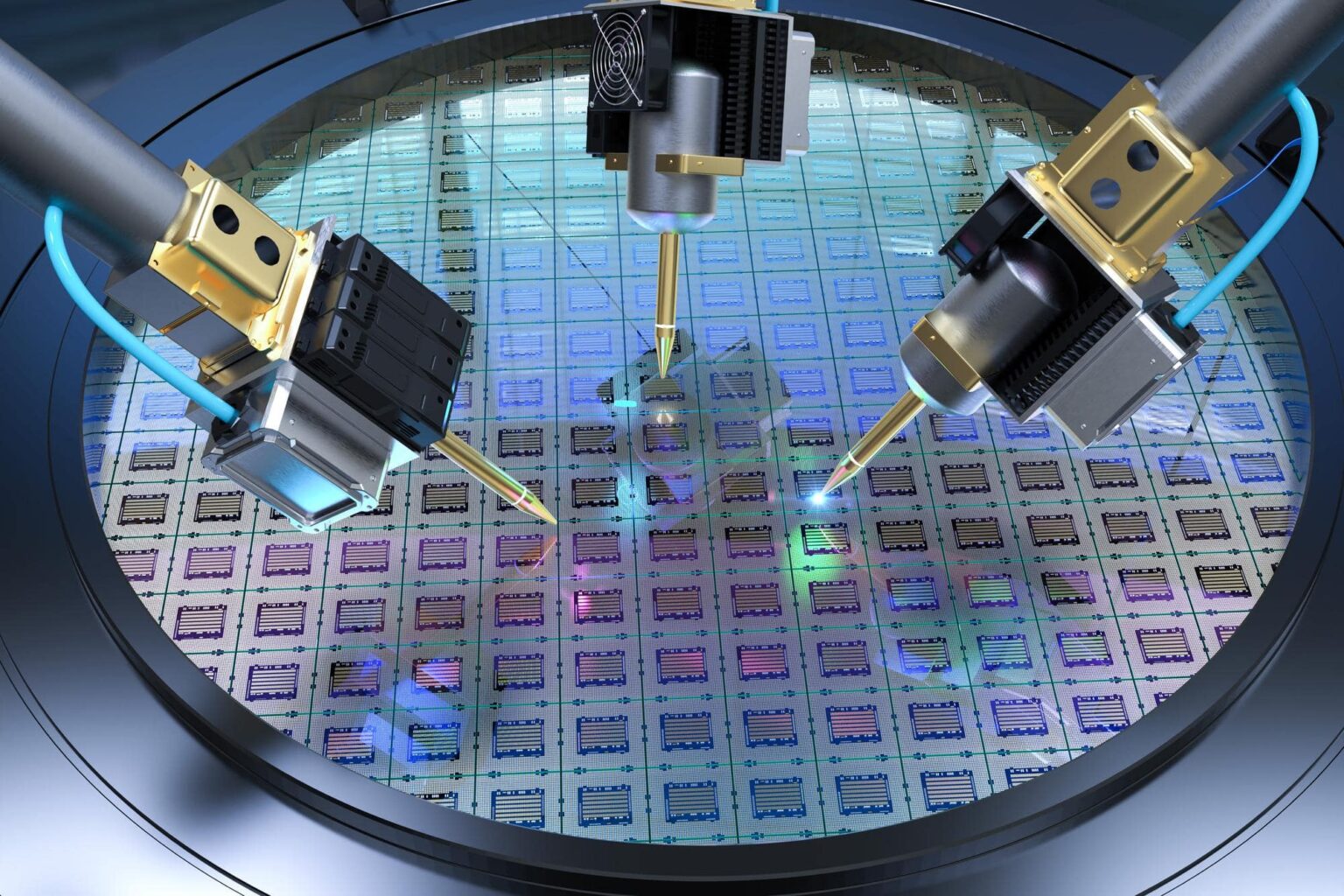

- Manufacturing Processes: Nanotechnology and advanced materials have the potential to improve conventional manufacturing processes. For example, nanoscale additives can enhance the performance of lubricants and cutting tools, reducing friction, wear, and tool damage. Nanofabrication techniques, such as molecular self-assembly and lithography, enable the precise manufacturing of micro and nanostructures.

- Environmental Sustainability: Advanced materials and nanotechnology contribute to environmental sustainability by enabling energy-efficient processes, lightweight materials that reduce energy consumption in transportation, and materials with improved recyclability. Nanotechnology also offers the potential for pollution remediation and water purification through the development of novel nanomaterials and nanocomposites.

The integration of advanced materials and nanotechnology into manufacturing processes holds immense potential for creating innovative products with enhanced properties, improving efficiency, and addressing environmental challenges. As these technologies continue to advance, their widespread adoption in various industries is expected to drive significant advancements in manufacturing capabilities.