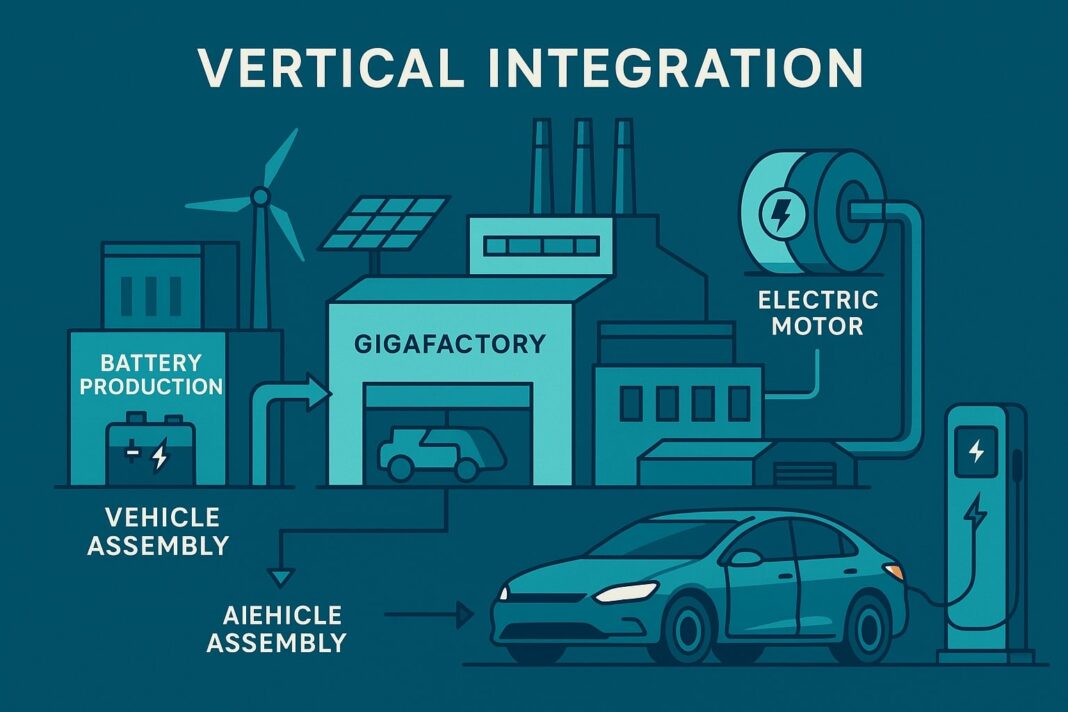

The electric vehicle (EV) industry is undergoing its biggest transformation since Tesla introduced the giga factory concept a decade ago. Today, the global shift to EV Manufacturing 2.0 is defined by vertical integration and the emergence of massive giga-ecosystems — interconnected industrial clusters where batteries, motors, electronics, software, and entire vehicles are built under one integrated framework.

From raw materials to recycling, automakers are consolidating the entire value chain to reduce cost, accelerate innovation, and secure long-term supply.

This is not just a manufacturing change — it is a global industrial revolution.

1. What Is EV Manufacturing 2.0?

Manufacturing 1.0 relied on outsourcing — automakers bought major components (engines, electronics, batteries) from suppliers.

Manufacturing 2.0 is different:

✔ Highly consolidated production

Automakers internalize battery cells, motors, power electronics, and software.

✔ End-to-end control of the supply chain

From material extraction → cell production → pack assembly → final vehicle.

✔ Integrated giga-ecosystems

Factories, suppliers, research labs, renewable energy plants, and recycling centers all in one zone.

Result:

Lower cost, faster production cycles, stronger performance, and far greater innovation.

2. Why Vertical Integration Is Now Essential

A. Battery supply is the new bottleneck

Batteries account for 35–40% of EV cost.

Automakers now build their own cell plants to:

-

Reduce dependency on CATL/BYD/LG

-

Customize chemistries

-

Secure long-term supply

-

Lower cost per kWh

B. Software-defined vehicles require in-house control

Traditional OEMs cannot compete without controlling:

-

Autonomous driving stack

-

Battery optimization

-

Infotainment systems

-

OTA updates

C. Global supply chain risks

Pandemics, geopolitics, and raw material shortages exposed fragility.

Vertical integration creates resilience.

D. Faster innovation cycles

Integration cuts development cycles from years to months.

3. The Rise of Giga-Ecosystems

Giga-ecosystems go far beyond a single gigafactory.

They include:

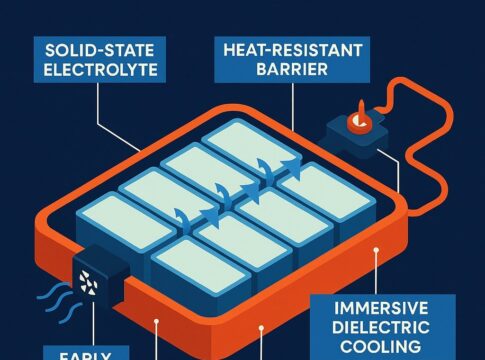

1. Battery cell manufacturing

LFP, NMC, semi-solid, sodium-ion, and eventually solid-state.

2. Module & pack assembly

3. Electric motor and inverter factories

4. Software & AI labs

- Autonomous driving

- Smart charging

- Digital twins

5. Renewable energy generation

- Solar farms

- Wind parks

- Energy storage facilities

6. Recycling and second-life battery centers

7. Logistics hubs & supplier parks

These ecosystem cities become self-sufficient industrial worlds, reducing cost and speeding innovation.

4. Case Studies: Who Is Leading EV Manufacturing 2.0?

Tesla: The Original Giga-Model

-

End-to-end integration

-

Cells, packs, motors, software, and vehicle assembly

-

Creating Giga cities in Texas, Berlin, Shanghai

BYD: The World’s Most Integrated EV Company

-

Self-produced batteries, chips, motors, semiconductors, BMS

-

Own raw material supply chain

-

“Blade Battery Ecosystem”

Rivian & Lucid

-

Bringing motors, power electronics, and packs in-house

-

Vertical integration as core strategy

Mercedes, VW & Hyundai

-

Developing “one roof” battery + EV component mega-campuses

-

Partnering with CATL and QuantumScape

India, UAE, and KSA

-

Government-backed giga-ecosystems:

- India’s PLI battery clusters

- UAE’s AI-driven EV hubs

- Saudi Arabia’s NEOM EV megazones

5. Benefits of Giga-Ecosystems

✔ Lower Manufacturing Costs

Integrated production eliminates middlemen.

✔ Faster R&D and Product Launches

Battery chemistry to drivetrain tuning all happens in one hub.

✔ Stronger Supply Chain Security

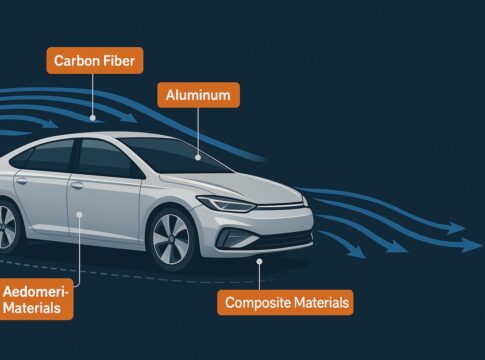

OEMs secure raw materials (lithium, nickel, graphite) internally.

✔ Sustainable Manufacturing

Energy reuse, onsite renewables, closed-loop recycling.

✔ Higher Quality Control

Reduced component variability.

6. The Future: Giga-Ecosystem 2030

By 2030, giga-ecosystems will evolve into self-learning, AI-driven factories.

Expected features:

- Fully automated robotic lines

- Digital twin monitoring for every vehicle

- Quantum-optimized supply chain planning

- Carbon-negative manufacturing

- AI that redesigns vehicles in real time

- Integrated EV + battery + recycling clusters

- These ecosystems will be the backbone of global EV dominance.

Conclusion

EV Manufacturing 2.0 marks a dramatic shift toward vertical integration and giga-ecosystem development.

Automakers who control the entire value chain — from minerals to software — will win the EV race.

The future belongs to companies that think bigger, build deeper, and move faster with full-stack manufacturing power.