The global electric vehicle (EV) industry is entering a major transformation. By 2026, supply chains will shift from global dependency—especially on China—to localized, regional manufacturing hubs. Government policies, rising transportation costs, geopolitical tensions, and the urgent need for resilient supply chains are pushing automakers and battery makers to “build local, source local, and sell local.”

This marks the biggest EV supply chain shake-up in history.

Why 2026 Is the Turning Point

1. New Localization Laws Take Effect

Several major policies go live fully by 2026:

- U.S. Inflation Reduction Act (IRA) rules

- EU Critical Raw Materials Act

- India’s PLI (Production-Linked Incentive) Scheme

- GCC and UAE EV manufacturing incentives

- Japan–South Korea battery partnerships

These policies provide tax credits only if materials, cells, and battery packs are sourced locally.

2. Battery Manufacturing Moves Closer to Demand Centers

By 2026:

- Over 200+ gigafactories will be operational globally.

- The U.S., EU, India, and the Middle East will have their first wave of localized battery plants.

- Automakers are shifting away from single-country dependency.

Localized gigafactories reduce:

- Cost per kWh

- Shipping delays

- Carbon footprint

- Political vulnerability

This makes EV production faster and cheaper.

3. Rise of “Mine-to-Motor” Regional Ecosystems

Countries are building full local ecosystems:

North America

-

Lithium from Nevada, Canada

-

LFP and NMC cell plants in the U.S.

-

Local cathode/anode manufacturing

-

Complete vehicle assembly

Europe

-

Norway–Sweden battery metals hub

-

Germany–France cell manufacturing

-

Spain–Italy pack assembly

India

-

Lithium refineries in Gujarat

-

Cell manufacturing clusters in Karnataka & Tamil Nadu

-

Growing demand for small EVs and two-wheelers

Middle East (UAE, KSA)

- EV assembly plants

- Battery recycling clusters

- Mining investments in Africa

Localization ensures supply stability and accelerates domestic EV growth.

4. The Battery Recycling Boom

By 2026, EV battery recycling becomes a multi-billion-dollar sector.

Why?

- Millions of EVs are reaching 7–10 years of life.

- Lithium, cobalt, and nickel prices are increasing.

- Local recycling reduces import dependency.

Countries are pushing “urban mining,” where used batteries are recycled locally to extract fresh lithium for new cells.

5. Solid-State Batteries Accelerate Localization

Solid-state batteries, expected to hit initial commercial deployment between 2025–2027, require:

- New material ecosystems

- Local R&D clusters

- Specialized manufacturing units

Because of this, automakers are partnering with domestic research centers to avoid foreign technology reliance.

6. Geopolitics Forces Supply Chain Redesign

The EV industry can no longer risk:

- Trade restrictions

- Sanctions

- Shipping disruptions

- Rising freight costs

- Over-dependence on one market

2026 becomes the year automakers build regional independence.

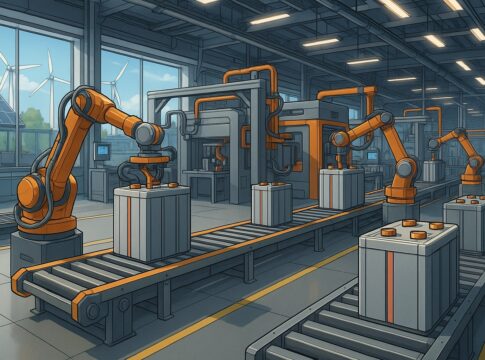

7. Automation Makes Local Manufacturing Affordable

Robotics and AI-driven factories reduce labor costs and make localization feasible everywhere.

By 2026:

- 60–70% of EV assembly lines will be automated.

- AI will manage inventory, shipping, and quality control.

- Predictive analytics will optimize material demand.

This closes the cost gap between Asia vs. Western manufacturing.

What Localization Means for the EV Market

1. Faster EV Delivery

Local manufacturing cuts delivery time by 40–60%.

2. Lower EV Costs

Reduced logistics and import taxes make EVs cheaper by $1,000–$3,000.

3. More Regional EV Brands

Localization creates opportunities for:

-

New EV startups

-

Battery pack manufacturers

-

Component suppliers

4. Job Creation

Millions of new jobs will emerge in:

-

Cell manufacturing

-

Charging infrastructure

-

Software AI for EV ecosystems

5. Stable & Predictable Supply Chains

Local ecosystems = less volatility.

Industries That Will Grow Because of Localization

✔ Battery Materials Processing

Lithium, graphite, manganese, and cobalt refining.

✔ EV Component Manufacturing

Motors, inverters, charging modules.

✔ Energy Storage Systems (ESS)

Home and grid-level storage solutions.

✔ Battery Recycling & Second-Life Batteries

A huge market emerging in 2026–2030.

✔ Gigafactory Automation

AI robotics and supply chain software.

Conclusion: 2026 Is the EV Localization Revolution

The EV industry is shifting from a global chain to regional independence. By 2026:

- EVs will be cheaper

- Batteries will be built closer to buyers

- Supply chains will be more stable

- Countries will compete to become EV manufacturing hubs

This is not just a trend — it’s the future of the automotive world.