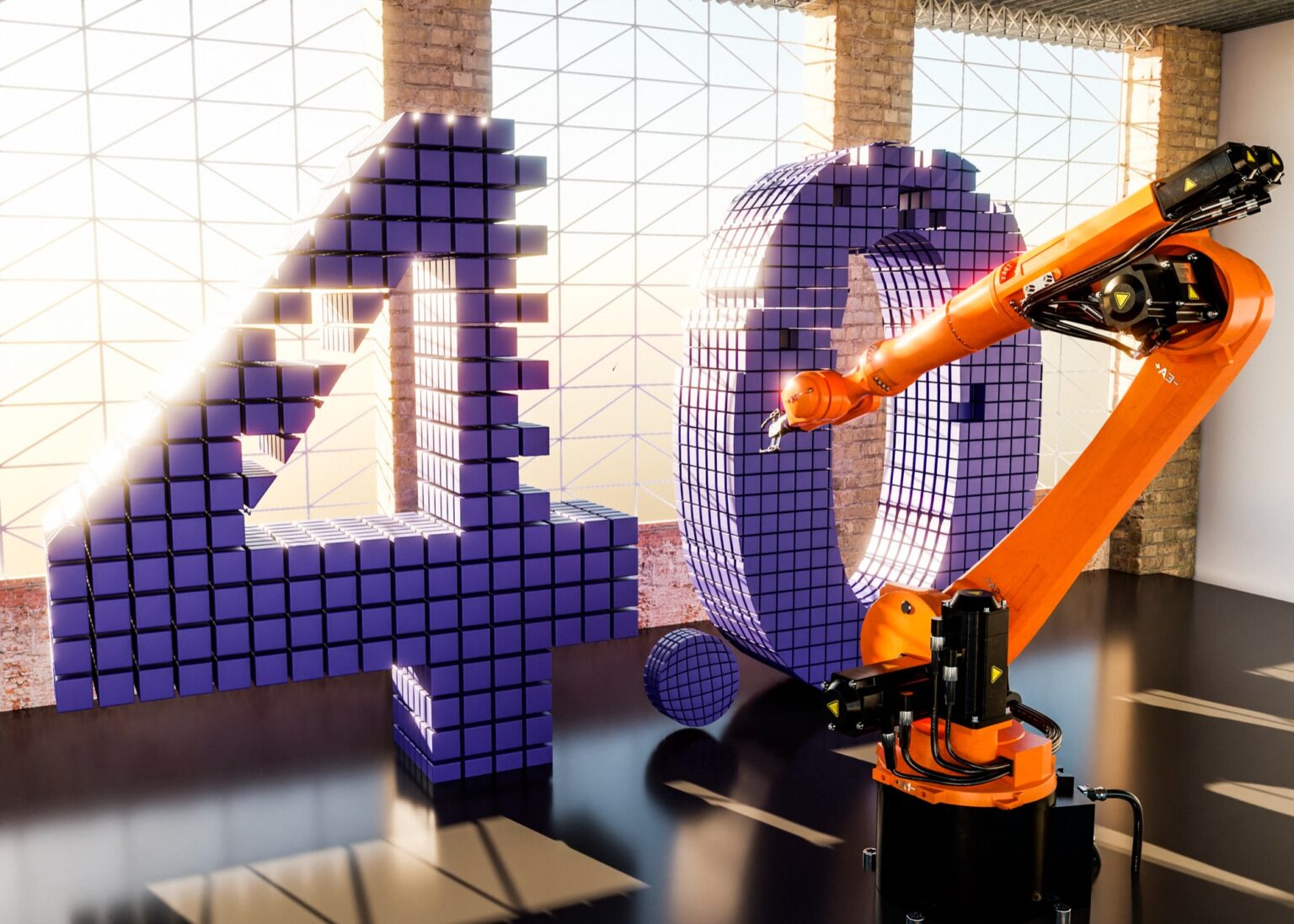

Industry 4.0, often referred to as the fourth industrial revolution, represents the digital transformation of manufacturing and automation processes. It leverages advanced technologies to create smarter, more efficient, and interconnected factories. Here are some key aspects highlighting the significance of Industry 4.0:

- Internet of Things (IoT) and Connectivity: Industry 4.0 relies on IoT devices and sensors to connect machines, systems, and products. These devices collect and transmit data, enabling real-time monitoring, control, and analysis of manufacturing processes. The interconnectedness of machines and systems facilitates data-driven decision-making and optimization of operations.

- Big Data and Analytics: Industry 4.0 leverages big data analytics to extract insights from vast amounts of data collected from various sources. Manufacturers can use advanced analytics techniques, such as machine learning and predictive analytics, to optimize production processes, identify patterns, detect anomalies, and improve efficiency. Data-driven decision-making enables proactive maintenance, resource optimization, and continuous improvement.

- Automation and Robotics: Industry 4.0 incorporates automation and robotics to enhance manufacturing processes. Intelligent machines, collaborative robots (cobots), and autonomous systems can perform repetitive and complex tasks with precision and speed. Automation improves efficiency, reduces errors, and enables flexible production through the use of adaptive manufacturing systems.

- Cyber-Physical Systems (CPS): Industry 4.0 integrates cyber-physical systems, which combine digital and physical elements to interact and communicate with each other. These systems encompass a wide range of technologies, including sensors, actuators, controllers, and software applications. CPS enable real-time monitoring, control, and optimization of manufacturing processes, leading to improved productivity and quality.

- Additive Manufacturing (3D Printing): Industry 4.0 embraces additive manufacturing, also known as 3D printing, as a disruptive technology. 3D printing allows the creation of complex, customized, and on-demand products. It offers greater design freedom, reduces material waste, and enables rapid prototyping and production. Additive manufacturing has the potential to transform supply chains and enable distributed manufacturing.

- Cloud Computing and Edge Computing: Industry 4.0 leverages cloud computing and edge computing for data storage, processing, and analysis. Cloud platforms provide scalable infrastructure and services for managing and analyzing large amounts of manufacturing data. Edge computing enables real-time processing and decision-making at the edge of the network, reducing latency and enabling near-instantaneous responses.

- Augmented Reality (AR) and Virtual Reality (VR): Industry 4.0 integrates AR and VR technologies for various applications in manufacturing. AR provides real-time information and guidance to workers, improving efficiency and accuracy in assembly, maintenance, and training processes. VR facilitates virtual simulations, allowing manufacturers to visualize and optimize production layouts, workflows, and training scenarios.

- Supply Chain Digitization: Industry 4.0 extends its impact beyond the factory floor to the entire supply chain. Digitization enables end-to-end visibility and integration of supply chain processes, including demand forecasting, inventory management, logistics, and customer engagement. The digitized supply chain improves responsiveness, reduces lead times, and enhances collaboration among suppliers, manufacturers, and customers.

Industry 4.0 represents a paradigm shift in manufacturing and automation, enabling manufacturers to achieve greater efficiency, flexibility, and innovation. By embracing advanced technologies and data-driven approaches, companies can optimize production processes, reduce costs, improve product quality, and meet the demands of a rapidly evolving market.