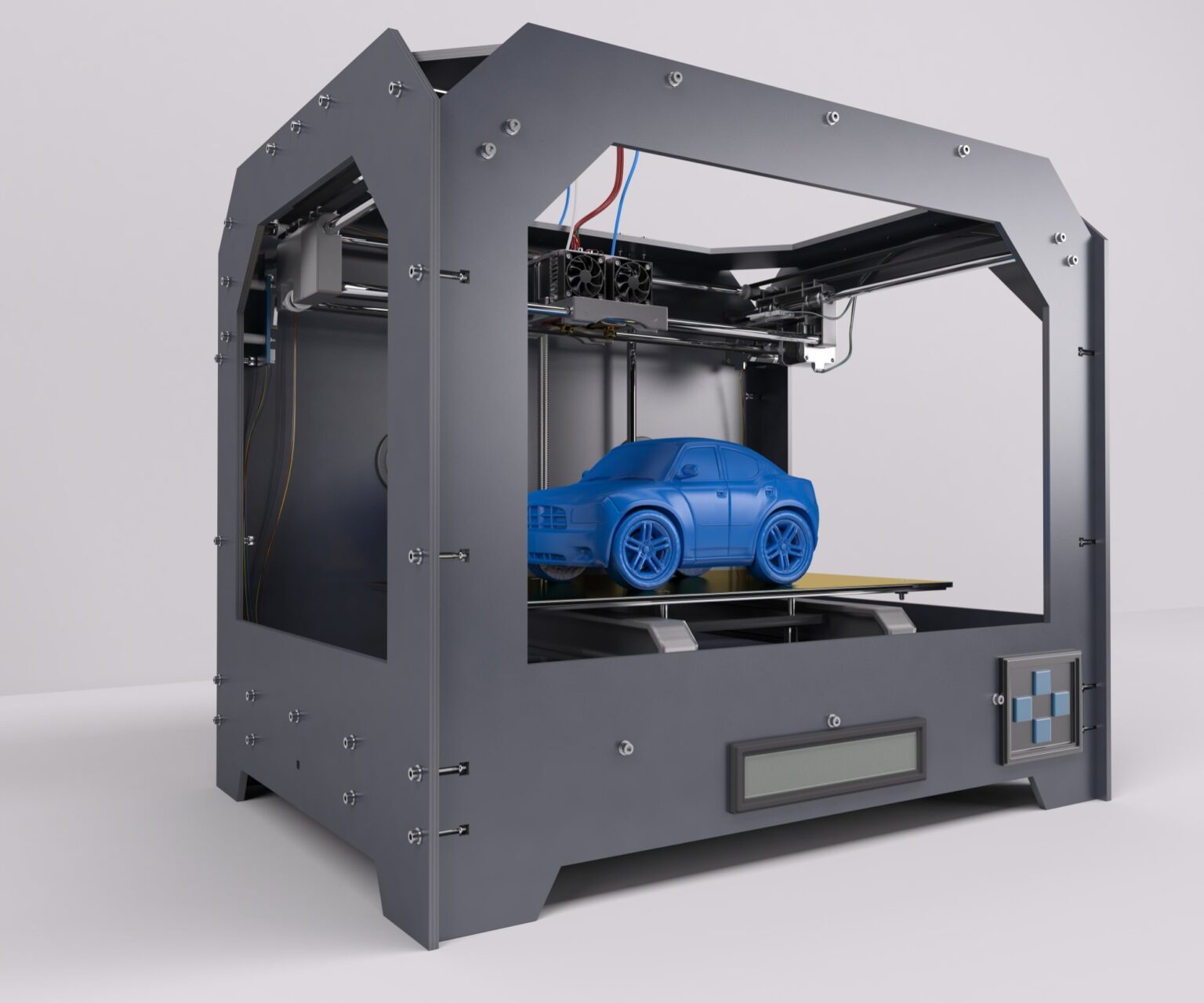

3D printing, also known as additive manufacturing, is a revolutionary technology that allows for the creation of three-dimensional objects by adding layers of material based on digital designs. It has gained significant attention and has diverse applications across various industries.

One of the key advantages of 3D printing is its ability to enable rapid prototyping. Product designers and engineers can quickly turn their digital designs into physical prototypes, allowing for faster iteration, testing, and refinement. This accelerates the product development process and reduces time-to-market.

In addition to prototyping, 3D printing is increasingly used for small-scale production. It offers a cost-effective and flexible manufacturing method, especially for complex geometries and low-volume production runs. This is particularly valuable in industries such as aerospace, automotive, and healthcare, where customized or specialized parts are needed.

The healthcare sector has witnessed significant advancements with 3D printing. It enables the production of patient-specific medical implants, prosthetics, and anatomical models for surgical planning. Customized medical devices can be tailored to individual patients, improving treatment outcomes and patient comfort.

Another area where 3D printing has made notable contributions is in the field of architecture and construction. Large-scale 3D printers can create building components, such as walls, facades, and structural elements, with enhanced design freedom and reduced material waste. This technology enables the construction of complex and customized structures, while also streamlining the construction process.

Furthermore, 3D printing has had a transformative impact on the manufacturing of complex and intricate objects. It allows for the production of lightweight and optimized components with internal structures that are difficult or impossible to achieve using traditional manufacturing methods. This can lead to improved performance, reduced material usage, and enhanced functionality in industries such as aerospace, automotive, and consumer goods.

3D printing also holds potential in the field of sustainability. It enables the use of recycled materials and reduces waste compared to subtractive manufacturing techniques. Additionally, 3D printing can localize production, reducing transportation and inventory costs, and facilitating on-demand manufacturing, which can contribute to a more sustainable supply chain.

Despite the advancements and applications of 3D printing, there are still challenges to overcome. These include material limitations, scalability for mass production, and the need for standardization and quality control in the manufacturing process.

In summary, 3D printing and additive manufacturing have revolutionized various industries by enabling rapid prototyping, small-scale production, customization, and complex geometries. They have applications in healthcare, architecture, manufacturing, and sustainability, among others. As the technology continues to evolve and overcome challenges, it holds the potential to transform traditional manufacturing and unlock new possibilities in design, production, and customization.